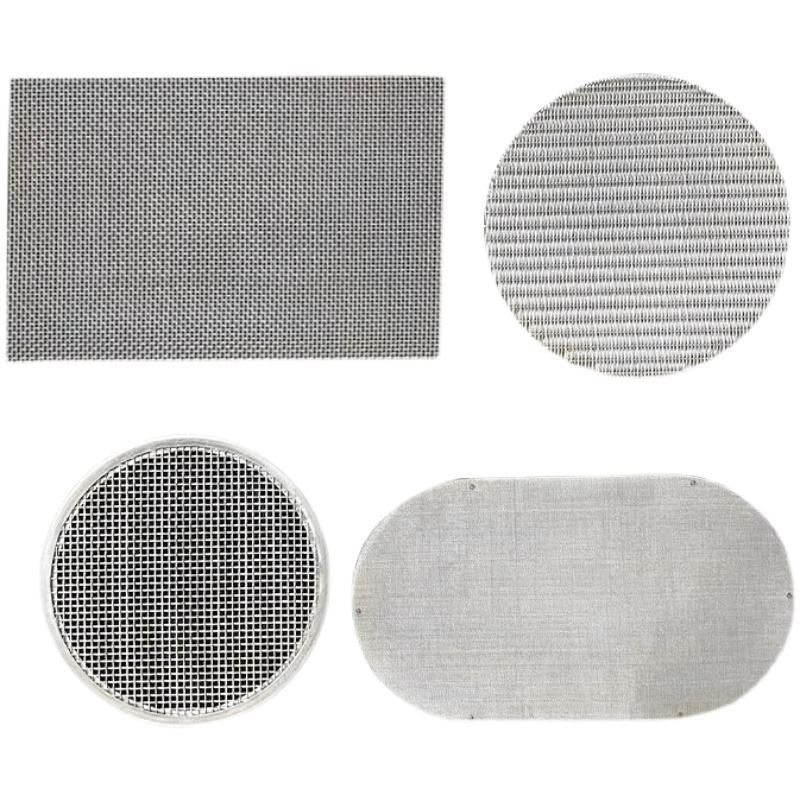

Mbadamba ụrọ kọfị na-esi nchara igwe anaghị agba nchara

Nkuzi ọdabara

1. Pịa kọfị ntụ ntụ na tamper

2. Tinye nha kwesịrị ekwesị nke ntupu nkewa mmiri

3. Tinye aka nke igwe kọfị n'isi isi

4. Lelee mmiri mmiri

Kedu ihe kpatara eji eji netwọk nkesa mmiri nke abụọ?

Netwọk nkesa mmiri nke abụọ na-ekewa nke ọma ntụ ntụ kọfị na isi ihe na-eme ka ọ dị ọcha

Àgwàma nke ntupu nke sintered

1. Ike dị elu na ezigbo nkwụsi ike: Ọ nwere ike ịrụ ọrụ dị elu na ike mkpakọ, nhazi dị mma, ịgbado ọkụ na mgbakọ mgbakọ, ma dị mfe iji.

2. Uniform na kwụ ọtọ kwụsiri ike: Enwere ike nweta ọrụ nzacha na-agbanwe agbanwe na nke na-agbanwe agbanwe maka nhazi nzacha niile, na ntupu anaghị agbanwe n'oge eji.

3. Wide ojiji gburugburu ebe obibi: Ọ nwere ike na-eji na ọnọdụ okpomọkụ nke -200 ℃ ~ 600 ℃ na filtration nke acid na alkali gburugburu ebe obibi.

4. Ọmarịcha arụmọrụ dị mma: mmetụta dị mma countercurrent ihicha, enwere ike iji ya mee ihe ugboro ugboro, ma nwee ogologo ndụ ọrụ (nwere ike ihicha ya site na mmiri na-adịghị mma, filtrate, ultrasonic, melting, baking, wdg).

Sintering mmepụta usoro

1. Obere okpomọkụ tupu ọkụ ogbo.N'oge a, mgbake nke ígwè, volatilization nke adsorbed gas na mmiri mmiri, decomposition na mwepụ nke na-akpụ gị n'ụlọnga na kọmpat tumadi ime;

2. Ọkara okpomọkụ kpo oku sintering ogbo.N'oge a, recrystalization na-amalite ime.N'ime ụmụ irighiri ihe ndị ahụ, a na-eweghachi ọka ndị ahụ mebiri emebi ma hazie ya ka ọ bụrụ ọka ọhụrụ.N'otu oge ahụ, oxides n'elu na-ebelata, na interface urughuru na-etolite a sintered olu;

3. Nchekwa okpomọkụ dị elu na-emecha usoro nkwụsịtụ.Diffusion na eruba na nke a ogbo na-n'ụzọ zuru ezu rụrụ na nso ẹkụre, na-akpụ a nnukwu ọnụ ọgụgụ nke mechiri emechi pores, na-anọgide na-ebelata, nke mere na pore size na ngụkọta ọnụ ọgụgụ nke pores na-ebelata, na njupụta nke sintered ahu bu budata. mụbara.