Mpempe akwụkwọ igwe anaghị agba nchara

Nkọwapụta

Ihe:Nri nri SS 304 316, ọla kọpa, wdg

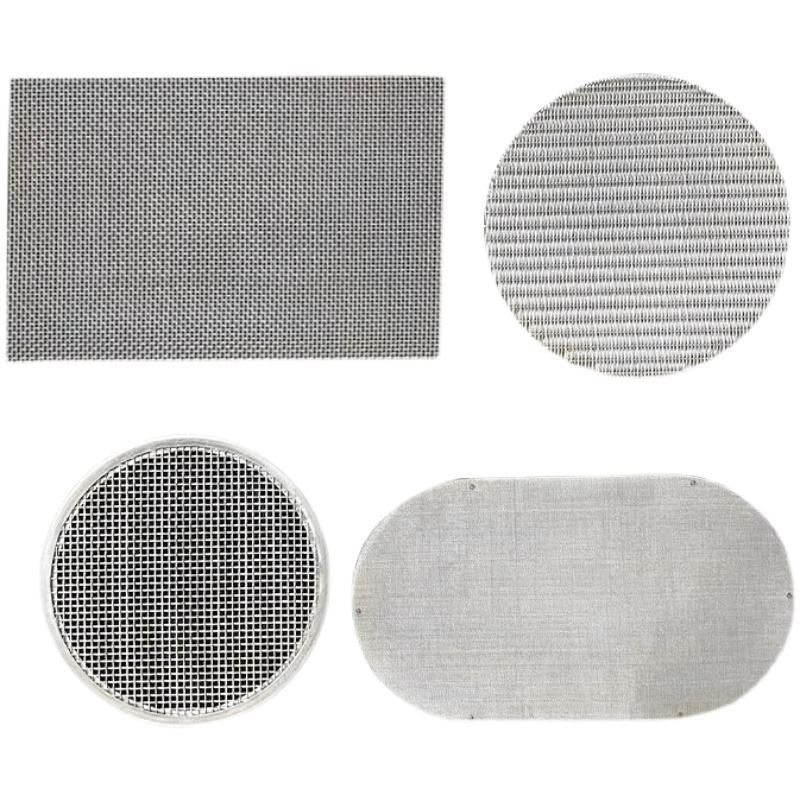

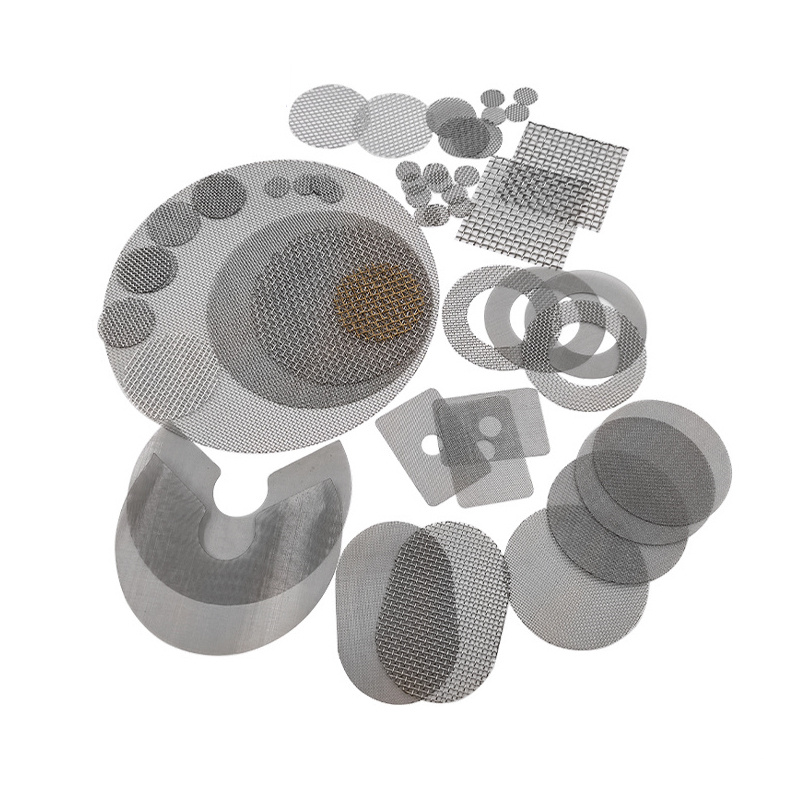

Ụdị:Udi okirikiri, akụkụ anọ udi toroidal udi, square udi, oval udi ọzọ pụrụ iche

oyi akwa:Otu oyi akwa, ọtụtụ oyi akwa

Gịnị bụ sintered ntupu?

A na-eme ntupu nke sintered site n'ịkọba ọtụtụ eriri igwe anaghị agba nchara nchara nke otu ụdị ma ọ bụ dị iche iche, mgbe ọ gbasasịrị, ịpị, ịtụgharị na usoro ndị ọzọ, a na-eme ya site na mgbasa na ngwọta siri ike mgbe ọkụ ọkụ ruo 1100 ° C. .Ihe nzacha ọhụrụ nwere ike igwe dị elu yana isi ike n'ozuzu ya.The waya ntupu nke ọ bụla oyi akwa nwere mwepu nke ala ike, ogbenye rigidity, na-ejighị n'aka ntupu udi, na nwere ike ezi uche dakọtara na chepụta efu size, permeability na ike àgwà nke ihe onwunwe, nke mere na ọ nwere magburu onwe filtration ziri ezi na filtration impedance., Mechanical ike, eyi iguzogide, okpomọkụ na-eguzogide na processability, n'ozuzu arụmọrụ bụ doro anya na mma karịa ndị ọzọ ụdị nzacha ihe dị ka sintered metal ntụ ntụ, ceramik, eriri, nyo ákwà, wdg.

A na-ahazi ntupu sntered dị ka ọkwa dị iche iche si dị na n'ụdị ntupu waya, ọkachasị gụnyere ntupu waya nke nwere akwa ise, ntupu igwe nwere ọtụtụ oyi akwa, ntupu eriri ọkpọ ọkpọ ọkpọ, ntupu eriri waya nwere oghere square na ntupu ute ụdị sintered waya ntupu.

Àgwàma nke ntupu nke sintered

1. Ike dị elu na ezigbo nkwụsi ike: Ọ nwere ike ịrụ ọrụ dị elu na ike mkpakọ, nhazi dị mma, ịgbado ọkụ na mgbakọ mgbakọ, ma dị mfe iji.

2. Uniform na kwụ ọtọ kwụsiri ike: Enwere ike nweta ọrụ nzacha na-agbanwe agbanwe na nke na-agbanwe agbanwe maka nhazi nzacha niile, na ntupu anaghị agbanwe n'oge eji.

3. Wide ojiji gburugburu ebe obibi: Ọ nwere ike na-eji na ọnọdụ okpomọkụ nke -200 ℃ ~ 600 ℃ na filtration nke acid na alkali gburugburu ebe obibi.

4. Ọmarịcha arụmọrụ dị mma: mmetụta dị mma countercurrent ihicha, enwere ike iji ya mee ihe ugboro ugboro, ma nwee ogologo ndụ ọrụ (nwere ike ihicha ya site na mmiri na-adịghị mma, filtrate, ultrasonic, melting, baking, wdg).

Enwere usoro atọ na usoro mmepụta sintering

1. Obere okpomọkụ tupu ọkụ ogbo.N'oge a, mgbake nke ígwè, volatilization nke adsorbed gas na mmiri mmiri, decomposition na mwepụ nke na-akpụ gị n'ụlọnga na kọmpat tumadi ime;

2. Ọkara okpomọkụ kpo oku sintering ogbo.N'oge a, recrystalization na-amalite ime.N'ime ụmụ irighiri ihe ndị ahụ, a na-eweghachi ọka ndị ahụ mebiri emebi ma hazie ya ka ọ bụrụ ọka ọhụrụ.N'otu oge ahụ, oxides n'elu na-ebelata, na interface urughuru na-etolite a sintered olu;

3. Nchekwa okpomọkụ dị elu na-emecha usoro nkwụsịtụ.Diffusion na eruba na nke a ogbo na-n'ụzọ zuru ezu rụrụ na nso ẹkụre, na-akpụ a nnukwu ọnụ ọgụgụ nke mechiri emechi pores, na-anọgide na-ebelata, nke mere na pore size na ngụkọta ọnụ ọgụgụ nke pores na-ebelata, na njupụta nke sintered ahu bu budata. mụbara.